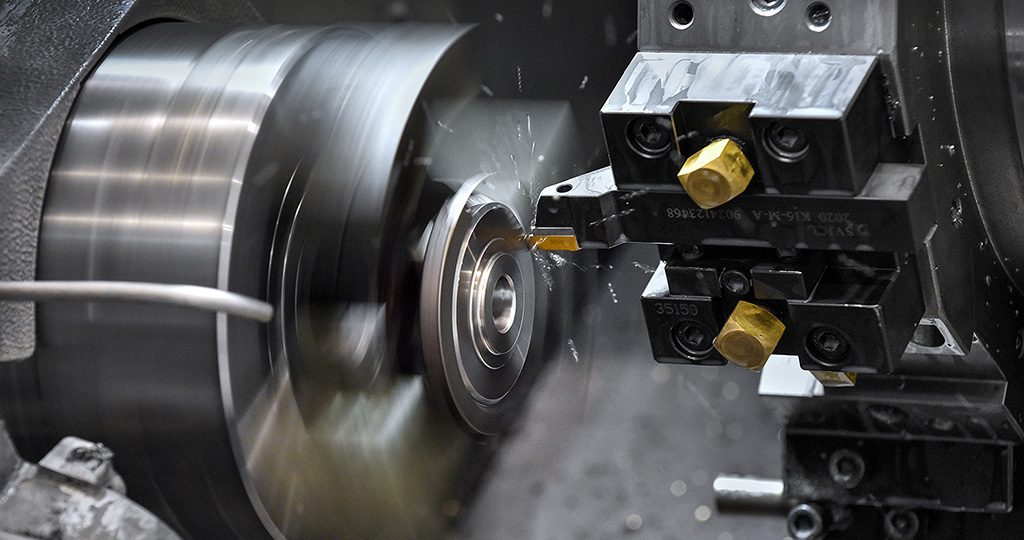

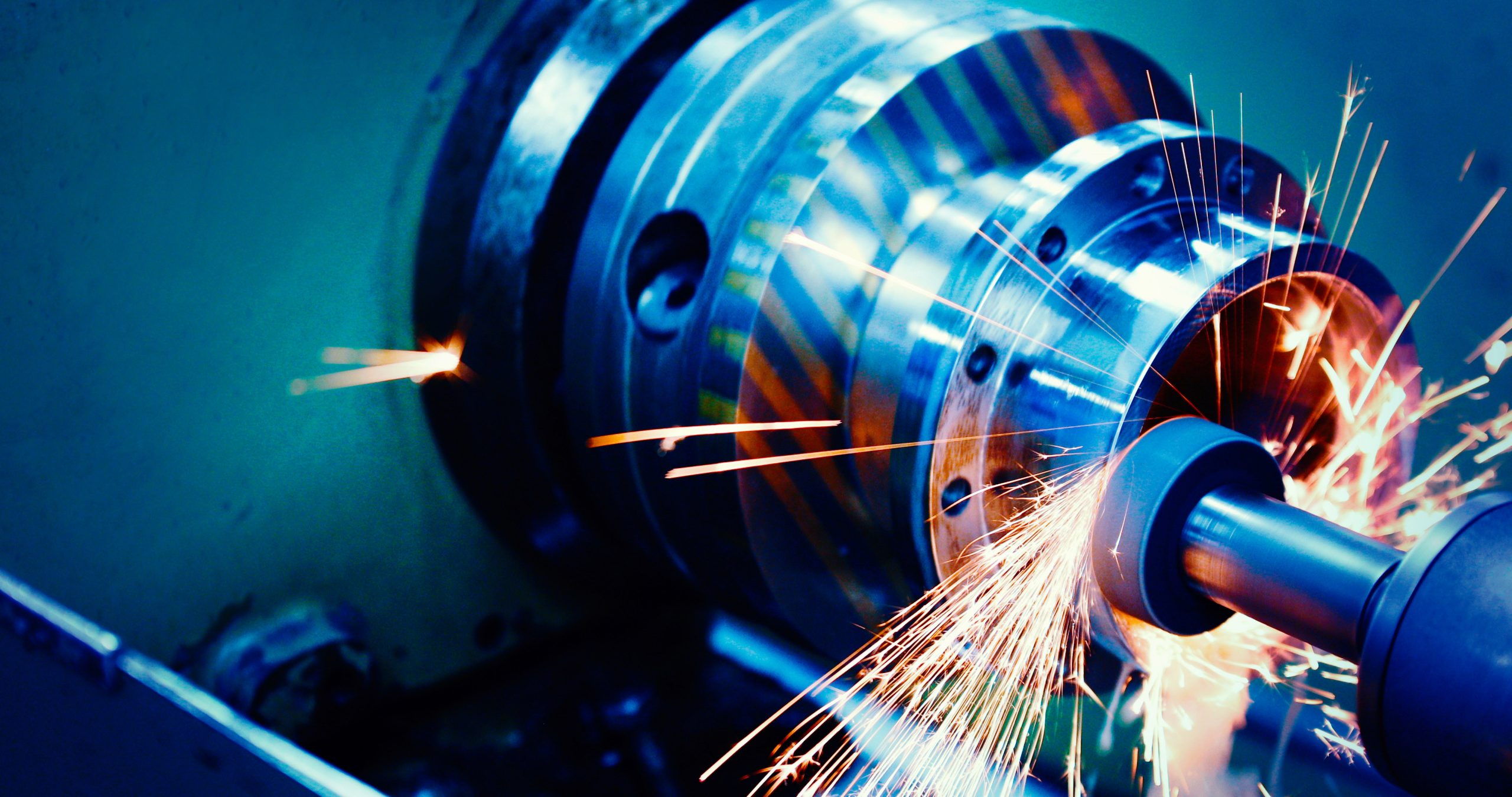

The principle of turning is that we use a single-pointed tool to create cylindrical and rounded shapes. In SECO Industries, s.r.o. we machine external and internal cylindrical, conical, spherical, planar, shaped surfaces by turning. Turning is also characterized by the tool being stationary for this operation while the workpiece rotates. Using a lathe and an implemented drill, we also drill conical holes in materials.

Order based turning

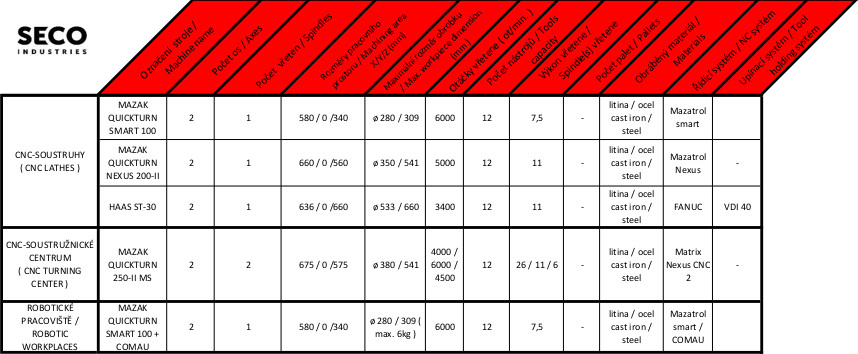

Thanks to our turning park and the tools we have at our disposal, we are very versatile and we can thus satisfy even demanding customers. We practice order based turning very often and each customer always has their specific requirements. Of course, we also provide order based cnc turning, where most of the work is provided by a machine center, such as the Mazak Quickturn 100, or the Mazak Quickturn nexus 200-II or Haas ST-30. All these turning centers are available to our customers.